| Model | 400P | 500P | 600P | 800P | 1000P | 1200P | 1600P | 2600P |

|

Engine Type |

CUMMINS | CUMMINS/CAT | CUMMINS/CAT | CUMMINS/CAT | WEICHAI | CUMMINS | CUMMINS | CUMMINS |

|

Max.Power(kw/HP) |

260/360 | 298/400 | 403/504 | 522/700 | 670/915 | 896/1200 | 1007/1350 | 1942/2000 |

|

Max.Frequency(rpm) |

2200 | 2100 | 2100 | 2100 | 2100 | 1800 | 1900 | 1900 |

| Max.Oil flow(L/min) | 400 | 500 | 630 | 800 | 800 | 1200 | 1600 | 2600 |

| Working Pressure

(bar) |

320 | 320 | 320 | 320 | 320 | 320 | 320 | 320 |

| Diesel TankVolume

(L) |

500 | 500 | 600 | 600 | 600 | 1000 | 1000 | 2150 |

| HydraulicTank

Volume(L) |

1400 | 1400 | 2000 | 2200 | 2200 | 4200 | 4200 | 5200 |

| SizeL*W*H(mm) | L 3900

W1520 H 2100 |

L 3900

W1520 H 2100 |

L 4500

W1820 H 2400 |

L 4550

W1850 H 2520 |

L 5650

W1920 H 2550 |

L 6050

W 2350 H 2820 |

L 6050

W 2350 H 2820 |

L 7800

W 2360 H 2750 |

| Weight(kg) | 6000 | 6000 | 9000 | 9300 | ..10500….. | ..20000…. | 20000 | 30000 |

| Suitable for

Vibro Hamme |

YZ-90D | YZ-100D

YZ-150B YZ-100VM |

YZ-180B

YZ-130VM |

YZ-230B

YZ-230F YZ-280L YZ-180VM |

YZ-250VM | YZ-300

YZ-300L YZ-400 YZ-300VM |

YZ-500B

YZ-360VM |

YZ-600 |

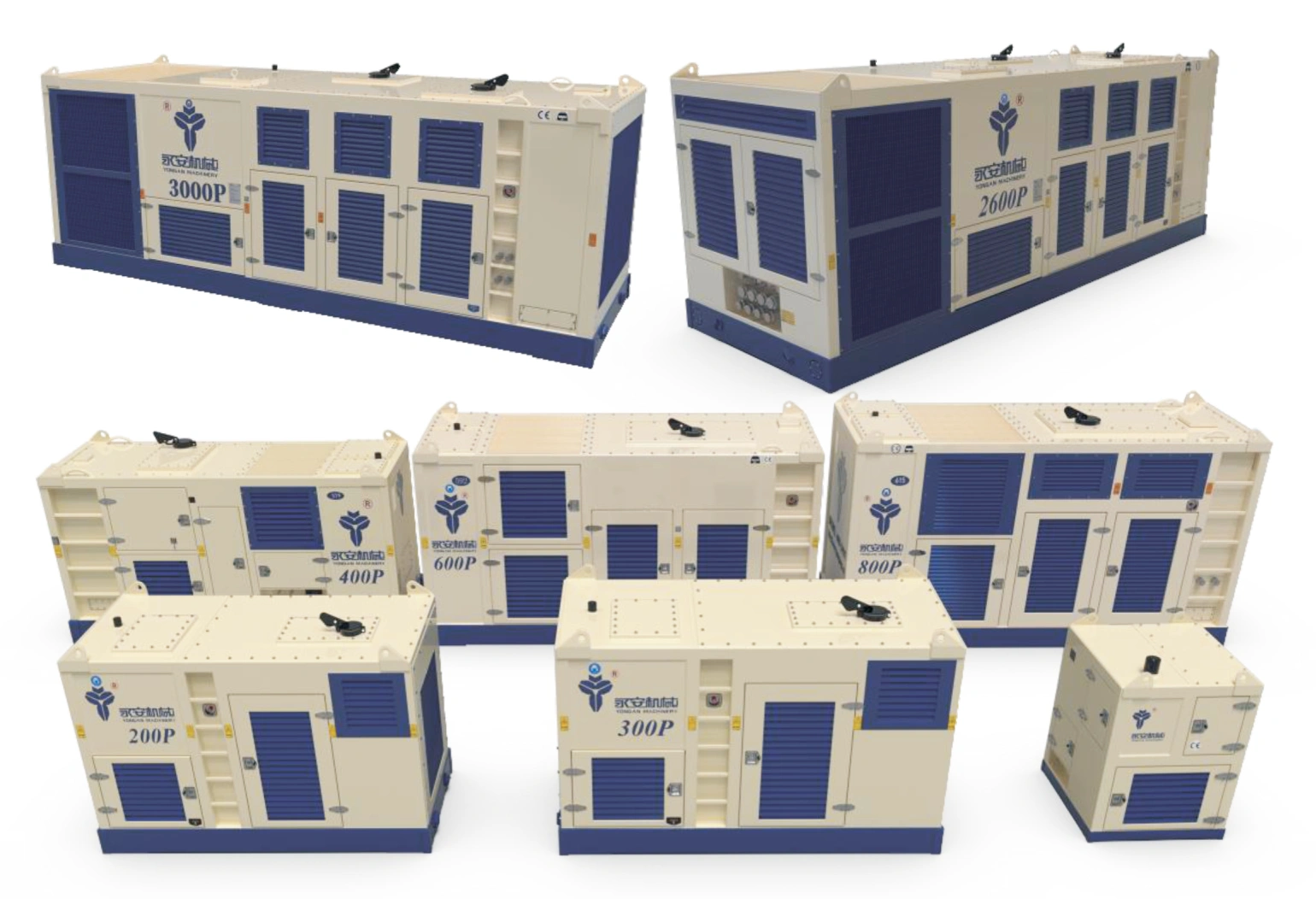

Power Pack

- Max.Power Range : 260-1915 (kW)

- Max.Frequency : 1500-2200 (rpm)

- Max. Oil Flow : 400-3500 (L/min)

- Working Pressure : 350 bar

- Diesel Tank Volume : 500-2500 L

- Hydraulic Tank Volume : 1400-7000 L

Zhenu power packs are driven by super top brand engines , hydraulic pumps , valves. The open loop hydraulic and cooling systems ensure a safe and reliable hydraulic operation and prevents overheating. The power pack can be adapted for extreme conditions such as freezing arctic environments or desert conditions with scorching heat. For arctic temperatures the design of this high-tech power packs incorporates insulation, heating and cooling to produce the same reliable performance. Hydraulic equipment such as the Impact Hammers, upending pile tool can also be driven using the power packs.

FEATURES

- Economical and durable

Zhenu power packs are equipped with CAT or Cummins engine, Rexroth hydraulic system and Germany Murphy control system. Power pack are connected to hammer by Eaton hoses, and the quick connectors are imported from Italy DNP. Excellent details make the whole equipment safe ,reliable and durable.

- Environmental

The low-noise, fuel-efficient power units comply with the latest exhaust emission regulations, equipped with a third exhaust gas countermeasure engine optional, or take a electric motor instead of diesel engine. Uses biodegradable fats and oils as grease.

- Quietness and portability

Compact and lightweight body that takes into consideration quietness and portability by making full use of soundproofing technology.

- Functional

Zhenu hydraulic power pack both can support for hydraulic vibro hammer and hydraulic impact hammer.

DETAILED INTRODUCTION

TECHNICAL DATA

PROJECTS

Premier Pile Hammer Manufacturer

Core Components Procurement and Inspection

• Core Components Procurement

Zhenu's vibro hammers insist on using high-quality components from international first-line brands, such as FAG bearings, Rexroth hydraulic systems, and CAT or Cummins engines.

• Quality Inspection

Conduct strict quality inspections on the purchased raw materials, including chemical composition analysis, mechanical property testing, dimensional accuracy measurement, etc.

Component Processing and Manufacturing

• Machining

Use CNC lathes, milling machines, drilling machines and other equipment to perform cutting processing on metal components to ensure dimensional accuracy and surface quality.

• Heat Treatment

Perform heat treatment processes such as quenching and tempering on key components to improve the hardness, strength and wear resistance of the components.

• Surface Treatment

Perform surface treatments such as electroplating and spraying on components to improve the corrosion resistance and appearance quality of the components.

Assembly and Commissioning

• Component Assembly

Assemble the processed components according to the assembly drawing to form various components of the hydraulic vibratory hammer, such as the hydraulic power unit, vibrator, fixture, etc.

• Final Assembly and Commissioning

Assemble all components as a whole, connect hydraulic pipelines, electrical circuits, etc., and then conduct commissioning.

Quality Inspection and Testing

• Appearance Inspection

Inspect the appearance of the hydraulic vibratory hammer to ensure that there are no obvious defects on the surface, the paint is uniform, and the markings are clear.

• Performance Testing

Conduct comprehensive performance tests on the hydraulic vibratory hammer, including testing parameters such as vibration frequency, amplitude, exciting force, and hydraulic system pressure.

• Reliability Test

Conduct reliability tests on the hydraulic vibratory hammer, and simulate actual working conditions for long-term operation tests.

Worldwide Shipping

• Delivery time guarantee

40 years of accumulation have enabled us to establish a solid strategic partnership with upstream core suppliers such as steel and hydraulic systems, ensuring a stable and timely supply of raw materials. For standard models, we have established a strong inventory of core components and complete machines, which can achieve "order-to-ship" and greatly shorten your waiting period.

•Specialization

We use fumigated wooden boxes that comply with IPPC/ISPM15 international standards. They are strong and durable and can effectively withstand the rough loading and unloading and complex environment during long-distance shipping. From packaging to customs declaration, every detail complies with international standards.

•Visualization & Traceability

We support customers to be able to see key production milestones and factory status, as well as the latest location, dynamic trajectory and estimated arrival time of the goods. Our logistics managers will closely monitor the status of your goods and proactively update you at key nodes (such as departure, arrival, and transit) to give you peace of mind.