| Model | YZ-90D | YZ-110D | YZ-150B | YZ-180B | YZ-230F | YZ-230B | YZ-280L | YZ-300 | YZ-300L | YZ-300F | YZ-360B | YZ-400 | YZ-400L | YZ-500B | YZ-600 | YZ-800B | YZ-1600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| EccentricMoment(kgm) | 26 | 32 | 46 | 51 | 33.5 | 76 | 92 | 137 | 150 | 52 | 102 | 226 | 200 | 250 | 300 | 550 | 1000 |

| Max. Frequency(rpm) | 1800 | 1800 | 1700 | 1800 | 2500 | 1700 | 1700 | 1410 | 1400 | 2300 | 1800 | 1300 | 1400 | 1400 | 1400 | 1350 | 1200 |

| Centrifugal force(kN) | 920 | 1140 | 1465 | 1810 | 2300 | 2410 | 2920 | 3000 | 3230 | 3020 | 3630 | 4185 | 4300 | 5370 | 6450 | 11000 | 15790 |

| Max. Pulling force(kN) | 400 | 600 | 600 | 600 | 800 | 800 | 800 | 2000 | 1600 | 800 | 1000 | 2500 | 2500 | 2500/3200 | 3500/4000 | 6000 | 9600 |

| Max. Amplitude(mm) | 32 | 33 | 25 | 32 | 20 | 32 | 30 | 37 | 30 | 16 | 29 | 40 | 37 | 33 | 30 | 35 | 28 |

| Max. Oil flow (L/min) | 350 | 480 | 620 | 680 | 800 | 800 | 890 | 1015 | 1220 | 1200 | 1200 | 1300 | 1220 | 1600 | 2400 | 3000 | 6070 |

| Size L*W*H (mm) | 1800*500*1760 | 1950*600*2100 | 3050*450*1940 | 2845*530*1880 | 2600*785*2410 | 2400*530*2380 | 3855*705*2035 | 2650*1150*4300 | 3460*850*2480 | 3855*705*2035 | 3150*650*2430 | 2700*1160*3980 | 4600*940*2650 | 3590*1280*4180 | 3400*1300*4200 | 5400*2000*4510 | 7830*1980*7420 |

| Weight W/O clamp(kg) | 3100 | 4000 | 5600 | 5900 | 6700 | 8180 | 9600 | 16000 | 14800 | 9600 | 10300 | 18500 | 21000 | 24800/30000 | 35600/41000 | 66300 | 135000 |

| Pipe Clamp | YZJ-80DCx2 | YZJ-80DCx2 | YZJ-120DCx2 | YZJ-120DCx2 | YZJ-160DCx2 | YZJ-160DCx2 | YZJ-160DCx2 | YZJ-160DCx2 | YZJ-160DCx2 | YZJ-200DCx2 | YZJ-200DCx2 | YZJ-200DCx2 | YZJ-200DCx2 | YZJ-200DCx4 | YZJ-200DCx4 | YZJ-320DCx4 | YZJ-320DCx6 |

| Steel Sheet Pile Clamp | YZJ-120 | YZJ-120 | YZJ-160 | YZJ-200 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | YZJ-320 | / | / | / | / |

| Power Pack Model | 400P | 500P | 600P | 600P | 800P | 800P | 800P | 1200P | 1200P | 1200P | 1200P | 1200P | 1200P | 1600P | 2600P | 3500P | 3000P*2 |

YZ-600

- Eccentric Moment: 300 kgm

- Max.Frequency: 1400 rpm

- Centrifugal force: 6450 kN

- Weight(W/O clamp): 41000 kg

- Max. Extracting force: 4000 kN

- Max. Amplitude: 30 mm

- Max. Oil Flow: 2400 L/min

- Size L*W*H: 3400*1300*4200 mm

- Clamp Type: Double Clamp

- Suggest Power Pack: 2600P

YZ series normal frequency hydraulic vibratory hammers are “workhorse” of vibration technology. Their robust yet simple design enables these units to be used for driving and extracting sheet piles, tubes and wherever there are no restrictions on the propagation of vibrations in the soil.The fixed eccentric moment makes this type of hammer a perfect fit for less sensitive, heavy duty jobs. Normal Frequency Vibratory Hammers are known for their reliability and power, especially when paired with our Power Pack. These sets have been carefully attuned to each other to ensure optimal performance.

Our hydraulic vibratory hammer adopts hydraulic components with global prestigious brands to ensure the system’s stability, such as CAT or Cummins engine, FAG bearing, Rexroth motor and pump etc,. Most components are standard components, convenient for replacement and maintenance. The specially designed hydraulic oil circuit system contributes to strong and stable centrifugal force, with working efficiency of over 90%. The finely designed structure gives the hydraulic vibratory hammer small volume, light weight and easy operation.

- Heavy metal filled eccentric block

Our eccentric blocks of hydraulic vibro hammers are filed with“heavy metal, that can produce more eccentric moment and bigger centrifugal force at same frequency comparing with all-iron eccentric blocks. So our vibro hammers drive piles more efficiently.

- Two stages damping system

Large elastomer provide excellent high frequency shock absorption and better protect crane boom. Small elastomer provide additional pulling force.

- German FAG high speed bearing

Bearings are most key components of vibro hammers. Via bearings the huge centrifugal force generated by the high-speed rotation of eccentric blocks is transmitted to piles. We adopts German FAG bearings, which have service life 5 times longer than ordinary bearings.

- REXROTH hydraulic system

Our all hydraulic pumps, motors, and hydraulic systems are from world top brand-Rexroth, which service life and performance stability are much far exceed general brands.

- Double lubrication cooling system

Double lubrication system make internal mechanical parts of vibro hammer more fully lubricated and the heat from gearbox can be quickly taken out. At same time, with the lubricating oil increasing the temperature rises more slowly.

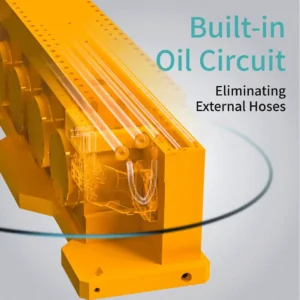

- Build-in Oil circuit

Hydraulic oil circuit is built in top cover of housing, eliminating 75% hoses and avoiding damaging while working, thereby reduce failure rate. At same time the structure of vibro hammer is more compact.

- Embedded motor

Our hydraulic motors are embedded or with external protective shell, reducing the damage chance of the motors due to collision during the operation, and greatly improve the reliability of the vibro hammers

- Offshore anti-corrosion technology spray

Using USA nano anticorrosion technology and 5+ types of surface treatment makes our products with good performance under offshore harsh conditions.

DETAILED INTRODUCTION

TECHNICAL DATA

RECOMMEND WITH

Pipe Clamp YZJ-200DCx4

- Holding Thickness: 0-85(mm)

- Clamping range: 700-3400(mm)

- Clamping Force: 2000kN x2

- Weight: 4360 kg

PROJECTS

|

|

|

|

Premier Pile Hammer Manufacturer

Core Components Procurement and Inspection

• Core Components Procurement

Zhenu's vibro hammers insist on using high-quality components from international first-line brands, such as FAG bearings, Rexroth hydraulic systems, and CAT or Cummins engines.

• Quality Inspection

Conduct strict quality inspections on the purchased raw materials, including chemical composition analysis, mechanical property testing, dimensional accuracy measurement, etc.

Component Processing and Manufacturing

• Machining

Use CNC lathes, milling machines, drilling machines and other equipment to perform cutting processing on metal components to ensure dimensional accuracy and surface quality.

• Heat Treatment

Perform heat treatment processes such as quenching and tempering on key components to improve the hardness, strength and wear resistance of the components.

• Surface Treatment

Perform surface treatments such as electroplating and spraying on components to improve the corrosion resistance and appearance quality of the components.

Assembly and Commissioning

• Component Assembly

Assemble the processed components according to the assembly drawing to form various components of the hydraulic vibratory hammer, such as the hydraulic power unit, vibrator, fixture, etc.

• Final Assembly and Commissioning

Assemble all components as a whole, connect hydraulic pipelines, electrical circuits, etc., and then conduct commissioning.

Quality Inspection and Testing

• Appearance Inspection

Inspect the appearance of the hydraulic vibratory hammer to ensure that there are no obvious defects on the surface, the paint is uniform, and the markings are clear.

• Performance Testing

Conduct comprehensive performance tests on the hydraulic vibratory hammer, including testing parameters such as vibration frequency, amplitude, exciting force, and hydraulic system pressure.

• Reliability Test

Conduct reliability tests on the hydraulic vibratory hammer, and simulate actual working conditions for long-term operation tests.

Worldwide Shipping

• Delivery time guarantee

40 years of accumulation have enabled us to establish a solid strategic partnership with upstream core suppliers such as steel and hydraulic systems, ensuring a stable and timely supply of raw materials. For standard models, we have established a strong inventory of core components and complete machines, which can achieve "order-to-ship" and greatly shorten your waiting period.

•Specialization

We use fumigated wooden boxes that comply with IPPC/ISPM15 international standards. They are strong and durable and can effectively withstand the rough loading and unloading and complex environment during long-distance shipping. From packaging to customs declaration, every detail complies with international standards.

•Visualization & Traceability

We support customers to be able to see key production milestones and factory status, as well as the latest location, dynamic trajectory and estimated arrival time of the goods. Our logistics managers will closely monitor the status of your goods and proactively update you at key nodes (such as departure, arrival, and transit) to give you peace of mind.