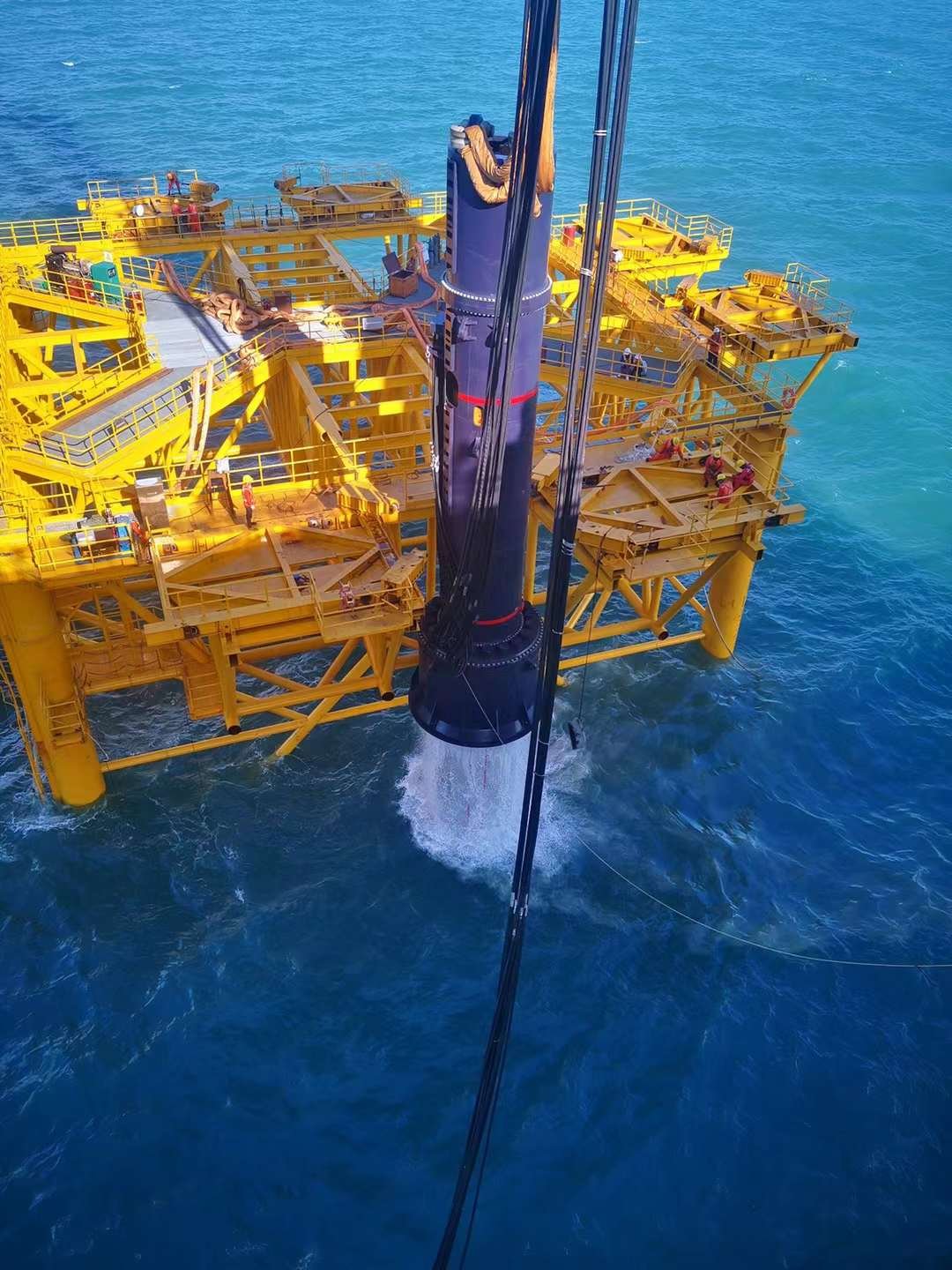

In March we completed the production of largest single-acting hydraulic impact hammer YC-180 in the world , soon it was put into use for the first time in the offshore wind farm area A project in Changle, Fujian. On the booster station platform in Area A of the project, although the sea is full of fog, with rich experience ,skilled technology and perfect cooperation between the project department of China Railway Bridge Bureau and our after-sales department YC-180 succeeded drive steel tubes to the designated depth and completed its debut.

The Changle Offshore Offshore Wind Farm Area A project is located at the north of the Taiwan Strait, one of the world’s three major storm surge areas, 35 kilometers northeast of Pingtan Bridge, and the center of the farm is 40 kilometers away from the coastline of Changle. The maximum water depth is 44 meters. The farm area is 32.1 square kilometers and the total capacity is 300 MW. Due to the combined effects of summer typhoons, winter monsoons and the “narrow tube effect” of the Taiwan Strait, the construction area is called “devil sea area” by local people due to the high winds, high waves and swelling throughout the year. The effective operation time is extremely short. The offshore wind farm project with the worst environment and the most difficult construction is also Chinese first attempt to build a offshore wind farm.

In this piling work the most difficult is the 4 steel pipes of the booster station platform. The 4 steel pipes is 94 meters in length, 3.2-3.8 meters in diameter, 5 cm in thickness, and about 400 tons in weight. The geological conditions of the construction sea area are: silt layer, medium-fine sand layer, and clay layer, the middle sand layer, the theoretical water depth is 39 meters to 44 meters, and the depth of penetration is 86 meters.

Based on analysis of geological report we found that driving the 4 piles of the booster station platform the maximum effective hammer energy of the hydraulic impact hammer needs to reach 2400KJ, but it is impossible to rent a impact hammer with such a large energy in the current market. In order to complete the piling construction of this project we work together with China Railway Bridge Bureau, Tongji University, Beijing Construction Mechanization Research Institute and other units, successfully rolled off the world’s largest single-acting hydraulic impact hammer YC-180 after more than a year of scientific research. In this project, the average penetration is 16 mm/hit and the average piling time is about 6 hours/pcs. The successful YC-180 application indicates that the Chinese large-scale hydraulic impact hammer has broken the monopoly of the West and has also saved the contractor tens of millions of yuan in equipment costs.

YC-180 hydraulic impact hammer is equipped with two 2600P power pack, with a maximum impact energy of 3000 kJ, oil flow 4800L/min, the ram is 180 tons, the maximum pile driving diameter can reach 7.5 meters, is currently the world’s largest single-acting hydraulic pile hammer.

The successful development of YC-180 hydraulic impact hammer indicates that we have the R&D, design and manufacturing capabilities of large-diameter hydraulic pile hammers for offshore wind farm and we have since entered the leading ranks of international heavy hydraulic pile foundation equipment. In future Zhenu machinery will continue providing high-end piling machinery for world.